| With the use of Moldex3D’s advanced simulation capabilities P.E.T.S. can accurately predict temperature, pressure, fiber orientation, viscous heating, and warpage in plastic parts.

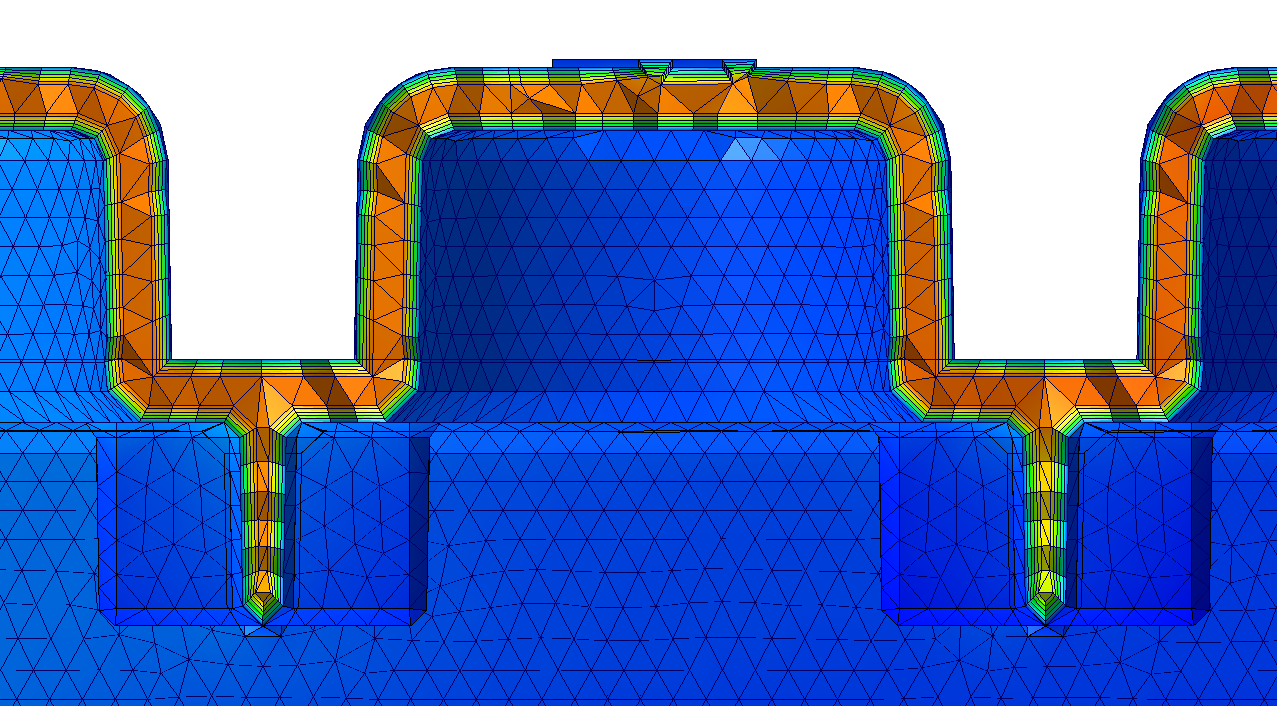

The exceptionally high levels of accuracy that we achieve in our analyses can be attributed to utilizing full 3D mesh for runners, cavities, cooling channels and inserts. 3D mesh, specifically Moldex3D’s proprietary Boundary Layer Mesh (BLM), allows for extra refinement through the thickness in order to capture the unique flow behavior of thermoplastics. Having this extra refinement through the thickness allows us to better simulate the viscous heating that occurs between the laminates of the flowing polymer, which is critical when balancing multi-cavity runners. Running an analysis with full Moldex3D BLM 3D mesh is the best way to validate final part or runner designs, as it can consider all of the challenging physics that occur in the injection molding process. Moldex3D analysis suitable for: |

|

|

Skip to content