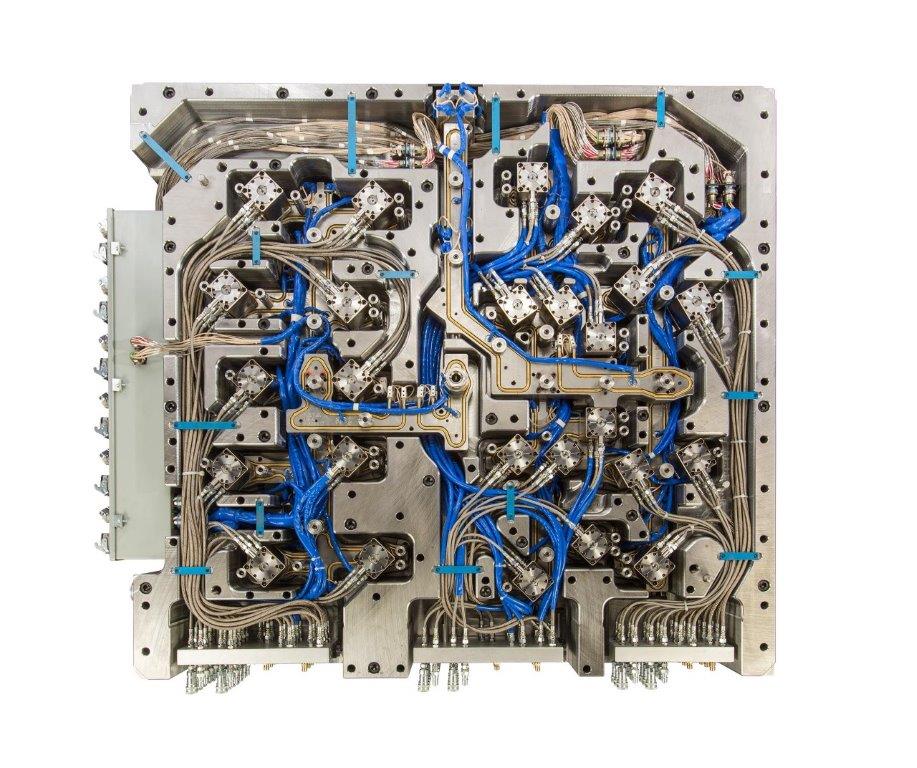

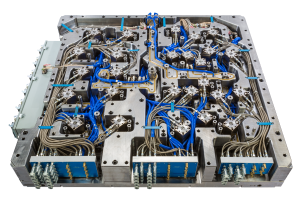

| Hot Half systems can range from one (1) drop designs, to incredibly elaborate, multi-manifold systems with dozens of drops and features. Perhaps the most critical ‘value-add’ feature of a hot half system is that it’s basically an easy to install, ‘plug and play’ system.

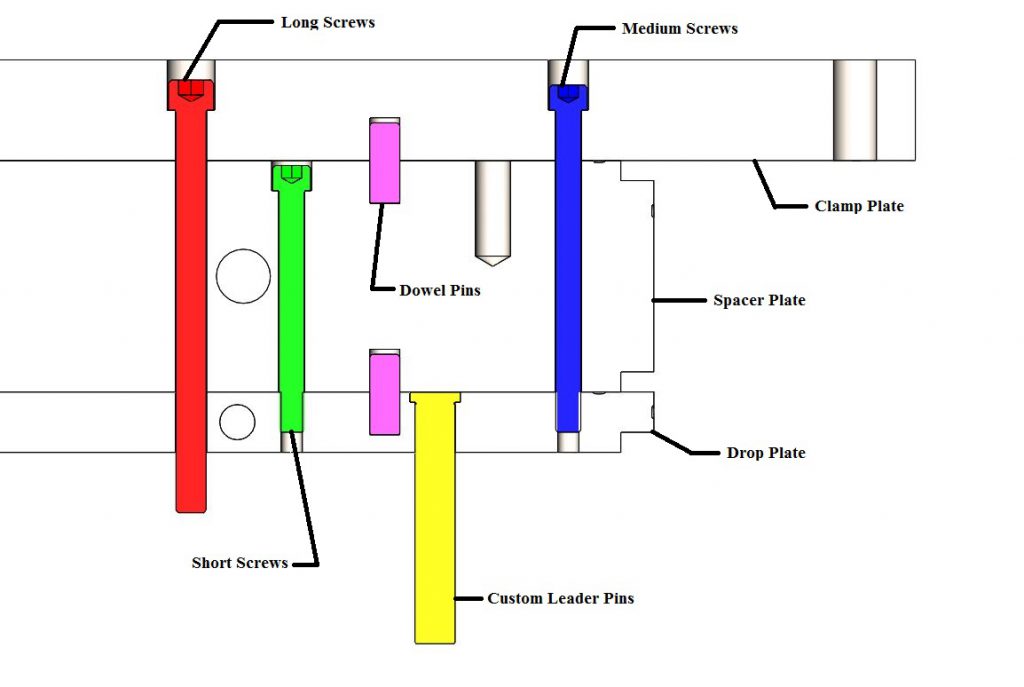

Included in every P.E.T.S. manifold hot half are three (3) plates; A clamp plate, a spacer plate and a drop plate. All of the screws to hold the three plates together are included, as well as the leader pins and alignment dowels. |

|

||

| This illustration depicts the ‘short’ screws which hold the drop plate and spacer plate together. The ‘medium’ screws which go through all three plates, and the ‘long’ screws, which are typically provided by the customer, to fasten the hot half to the mold.

The leader pins are generally basic, but can be custom or altered to meet specific customer needs. If all three plates are solid and not in multiple pieces, two (2) dowels are used to align the drop plate to the spacer plate, and two (2) more to align the spacer plate and the clamp plate. |

|

||

|

|

|

|

|